Hi to all,

a little update for @arit and a question for @jasonXu.

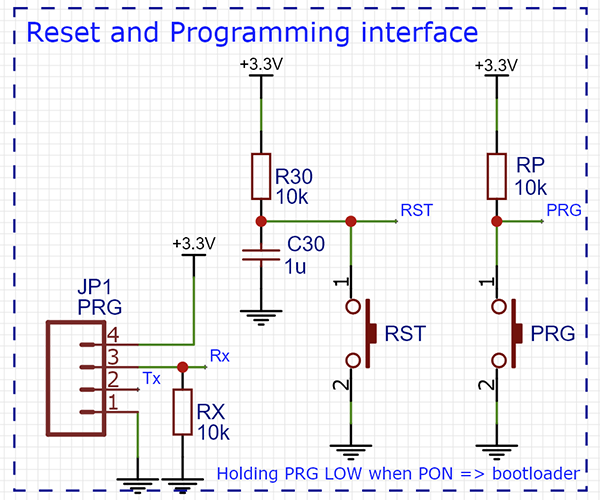

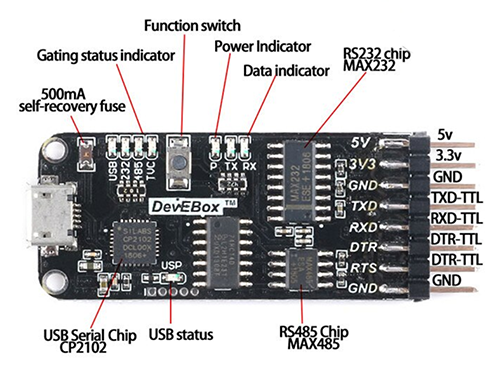

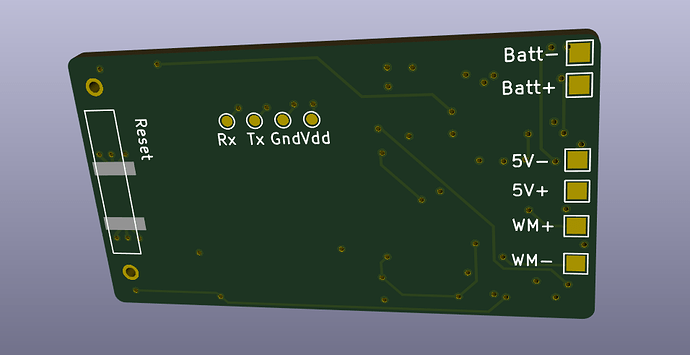

I use the proposed circuit above and all works very well for flashing my custom pcb and adapt for enclosing my device and make it waterproof. So @arit thanks for your advice! This is the choices I made

-Instead a button for Reset, I use a reed switch. When I want to reset my PCB without opening the case, I use a magnet.

-I design 4 tests points on my PCB and flash it with my 4xPogos pins on my last picture.

One of my mistake was to place a physical button for the PRG pin. On the next prototype I will use a simple jumper (reduce cost and increase ergonomy for flashing)

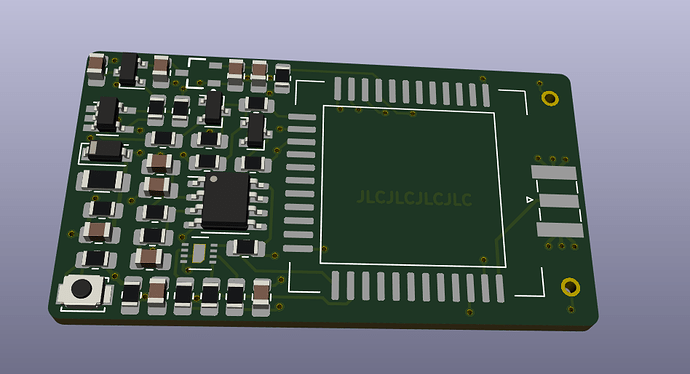

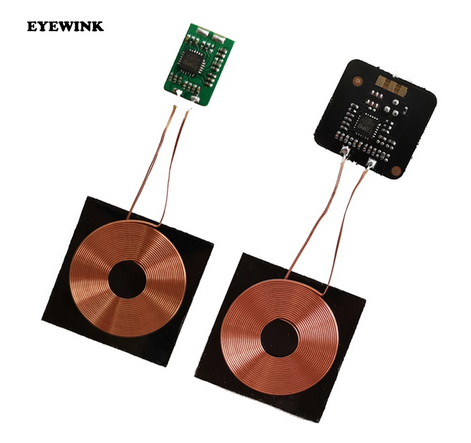

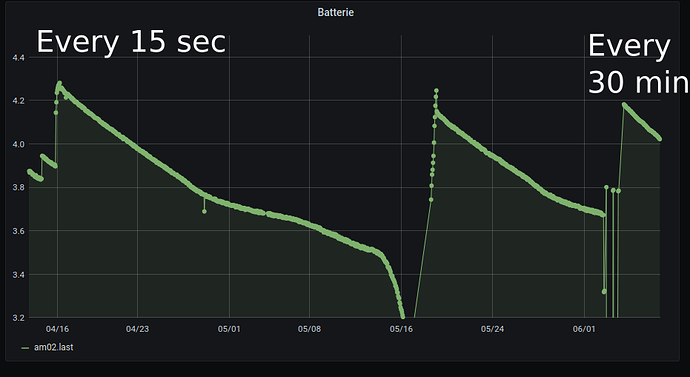

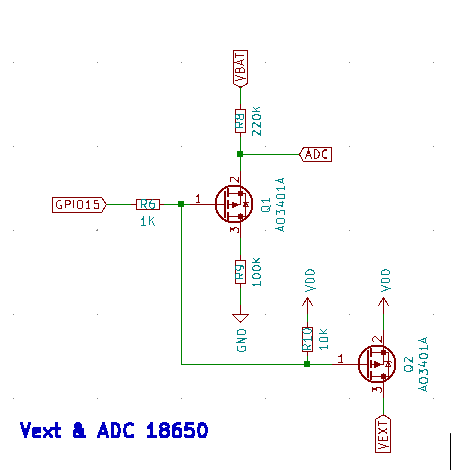

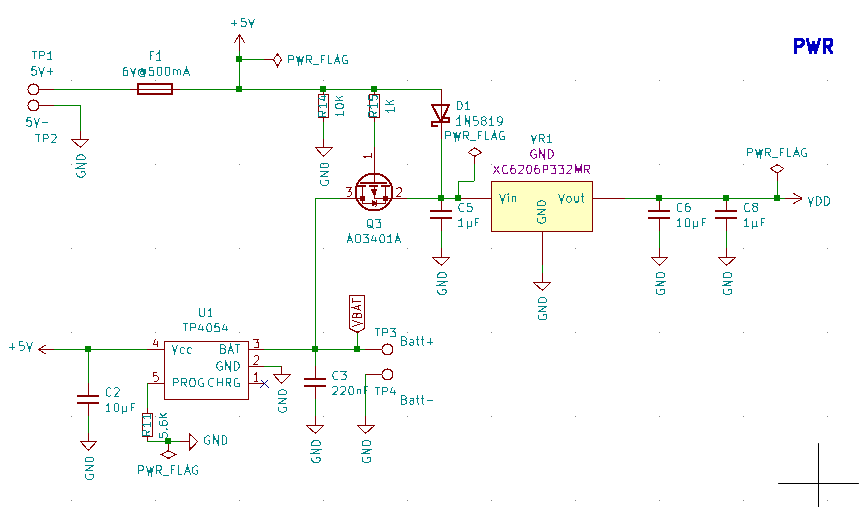

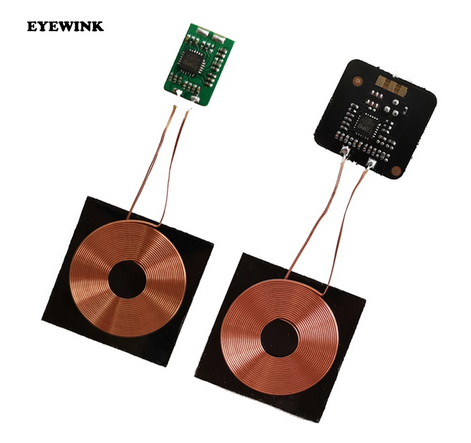

For power management I use the TP4054 for charging a 18650 battery. Instead of using a solar panel, I use a 5V induction charging coil wich permit to charge the device without opening the case.

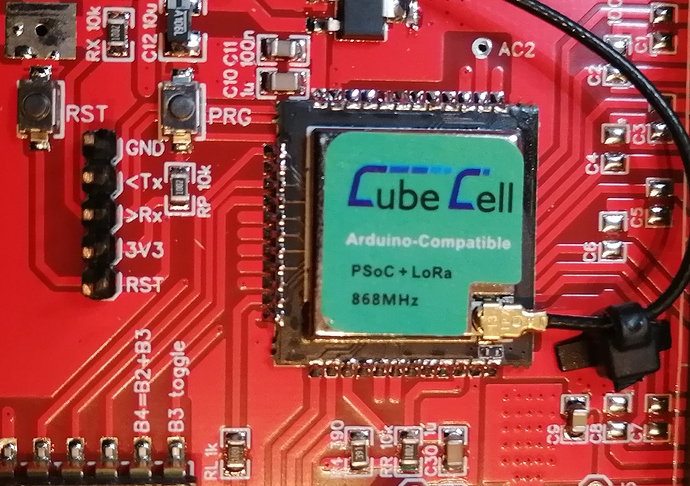

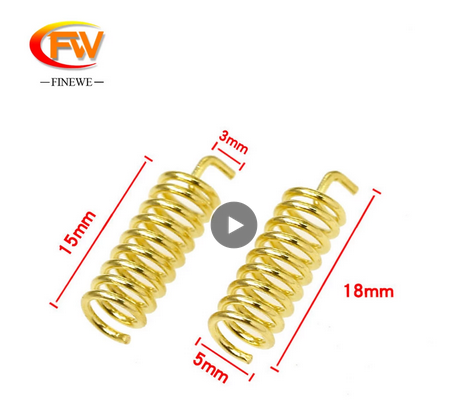

For the next PCB (and I hope with a new module  from Heltec) I will try to make a good RF section, as I am not a specialist it’s like black magic to make an external SMA antenna connector. I desolder the 0ohm resistor near the µFL connector on the module and I design on Kicad an SMA board edge connector with 50ohm impedance trace. I simply solder a 868MHz helical antenna on the positive side.

from Heltec) I will try to make a good RF section, as I am not a specialist it’s like black magic to make an external SMA antenna connector. I desolder the 0ohm resistor near the µFL connector on the module and I design on Kicad an SMA board edge connector with 50ohm impedance trace. I simply solder a 868MHz helical antenna on the positive side.

I will also take more time to place the tests points for flashing.

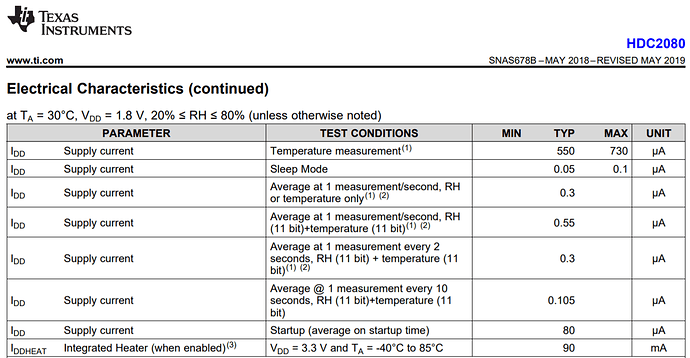

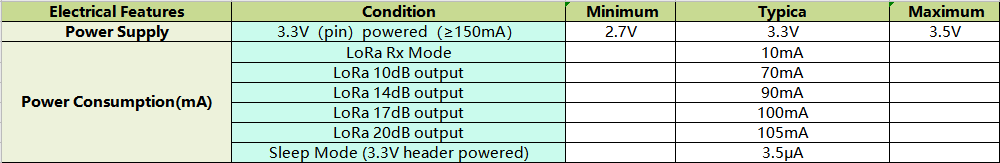

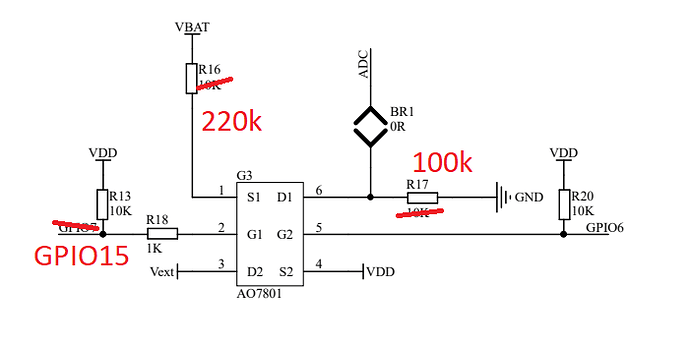

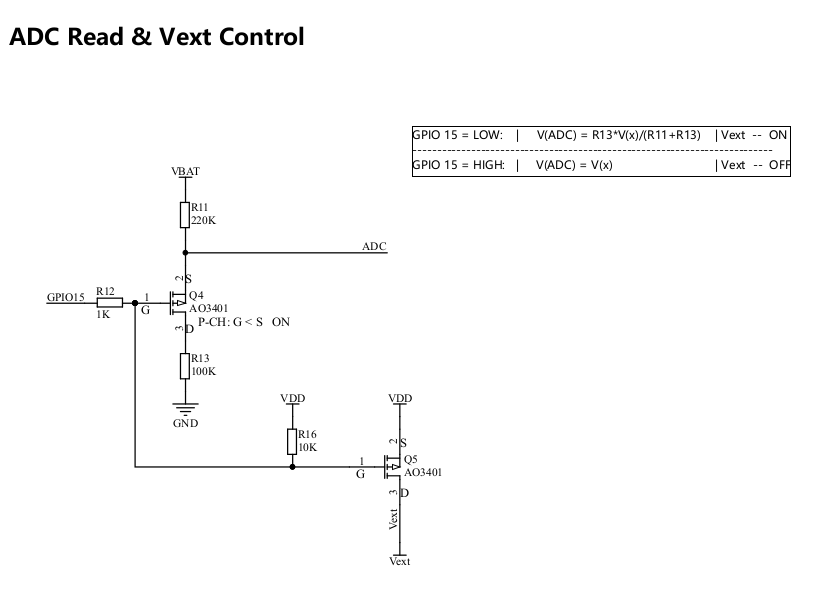

For @jasonXu, I want to use another temperature sensor (actually SHT31) wich consume current for readind humidity that I don’t use. @ksckung proposed advice me for powering my sensors on http://community.heltec.cn/t/custom-pcb-htcc-am02-on-kicad/3376/12

What kind of temperature sensor (SMC component) could you propose for the lowest consumption and avalaible libraries (maybe some of Heltec boards have temperature sensor with low power consumption.

This is some picture of the PCB 4 layers (newbie here, if someone see obvious design mistakes please let me know because there is a lot of stuff to know about pcb design).

I hope it will help someone as you guys helped me for my first newbie PCB design!

Can’t wait to see next modules from Heltec!