Here is a sample sketch that will setup the ADC reads (with per board EFuse calibration conversion/compensation), ensures some settle time for GPIO pins to ADC, adds in a sample / averaging buffer, has low voltage cutoff to deep sleep, uses light sleep if on battery mode at some threshold, and works with both V2.0 and V2.1 boards.

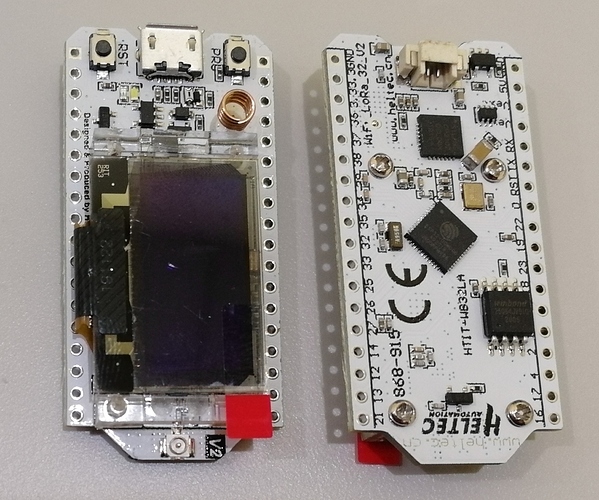

Note: I’m not sure why I can’t set GPIO21 LOW in setup and never digital write it low again, but have to continually assert it low in the ADC reading routines (this must have been my original issue with floating values and why I couldn’t get things functioning well…once I put the GPIO21 drive low in the loop at each ADC scan, it works). Something in my routines is turning off GPIO21 or something in the OLED drivers is…

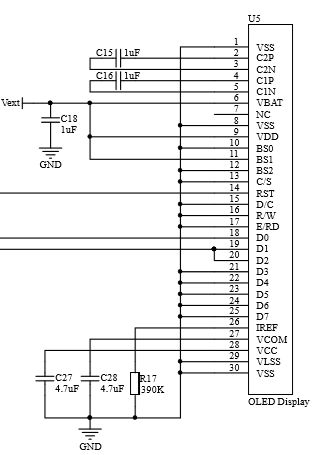

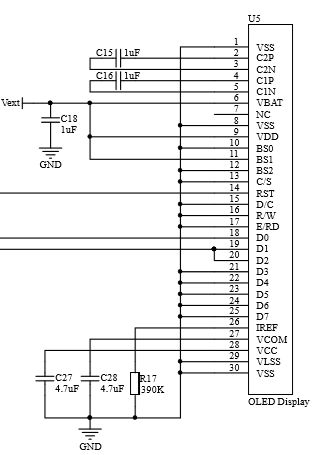

Originally, I tried to set this up to just pulse the GPIO21 low and connect the ADC read during the scan and then turn GPIO21 back off, but it appears the OLED display is now powered off of Vext since V2.0 and flipping GPIO21 high disconnects Vext from 3.3v now. The OLED seems to still work, just lower brightness, which I can only assume is because the display is powering from forward biasing input clamps from I2C SCL/SDA when writing…anyway…pretty obvious from the V2.0 schematic, you shouldn’t raise GPIO21 high if you want to use OLED…

// Heltec WiFi LoRa V2 battery read example

// by Jeff McClain jeff@themcclains.net

//

#include <Arduino.h>

#include <esp_adc_cal.h>

#include <driver/adc.h>

#include "heltec.h"

#define MAXBATT 4200 // The default Lipo is 4200mv when the battery is fully charged.

#define LIGHT_SLEEP_VOLTAGE 3750 // Point where start light sleep

#define MINBATT 3200 // The default Lipo is 3200mv when the battery is empty...this WILL be low on the 3.3v rail specs!!!

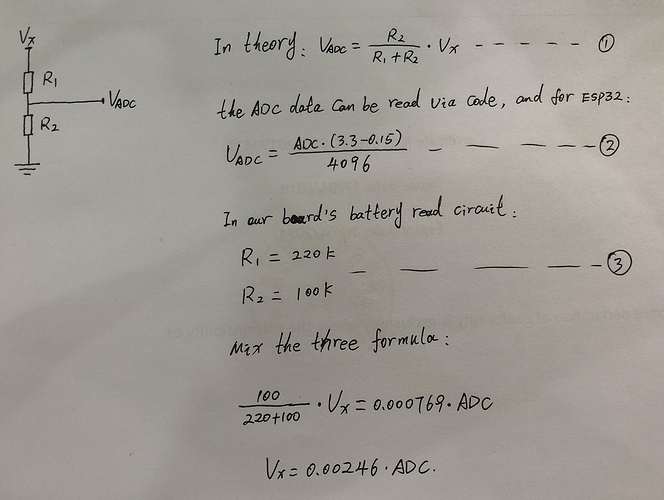

#define VOLTAGE_DIVIDER 3.20 // Lora has 220k/100k voltage divider so need to reverse that reduction via (220k+100k)/100k on vbat GPIO37 or ADC1_1 (early revs were GPIO13 or ADC2_4 but do NOT use with WiFi.begin())

#define DEFAULT_VREF 1100 // Default VREF use if no e-fuse calibration

#define VBATT_SAMPLE 500 // Battery sample rate in ms

#define VBATT_SMOOTH 50 // Number of averages in sample

#define ADC_READ_STABILIZE 5 // in ms (delay from GPIO control and ADC connections times)

#define LO_BATT_SLEEP_TIME 10*60*1000*1000 // How long when low batt to stay in sleep (us)

#define HELTEC_V2_1 1 // Set this to switch between GPIO13(V2.0) and GPIO37(V2.1) for VBatt ADC.

#define VBATT_GPIO 21 // Heltec GPIO to toggle VBatt read connection ... WARNING!!! This also connects VEXT to VCC=3.3v so be careful what is on header. Also, take care NOT to have ADC read connection in OPEN DRAIN when GPIO goes HIGH

#define __DEBUG 0 // DEBUG Serial output

uint16_t Sample();

void drawBattery(uint16_t, bool = false);

esp_adc_cal_characteristics_t *adc_chars;

void setup() {

while (! Serial);

delay(20);

// Characterize ADC at particular atten

#if (defined(HELTEC_V2_1))

adc_chars = (esp_adc_cal_characteristics_t*)calloc(1, sizeof(esp_adc_cal_characteristics_t));

esp_adc_cal_value_t val_type = esp_adc_cal_characterize(ADC_UNIT_1, ADC_ATTEN_DB_6, ADC_WIDTH_BIT_12, DEFAULT_VREF, adc_chars);

adc1_config_width(ADC_WIDTH_BIT_12);

adc1_config_channel_atten(ADC1_CHANNEL_1,ADC_ATTEN_DB_6);

#else

// Use this for older V2.0 with VBatt reading wired to GPIO13

adc_chars = (esp_adc_cal_characteristics_t*)calloc(1, sizeof(esp_adc_cal_characteristics_t));

esp_adc_cal_value_t val_type = esp_adc_cal_characterize(ADC_UNIT_2, ADC_ATTEN_DB_6, ADC_WIDTH_BIT_12, DEFAULT_VREF, adc_chars);

adc2_config_channel_atten(ADC2_CHANNEL_4,ADC_ATTEN_DB_6);

#endif

#if defined(__DEBUG) && __DEBUG > 0

Serial.printf("ADC Calibration: ");

if (val_type == ESP_ADC_CAL_VAL_EFUSE_VREF) {

Serial.printf("eFuse Vref\n");

} else if (val_type == ESP_ADC_CAL_VAL_EFUSE_TP) {

Serial.printf("Two Point\n");

} else {

Serial.printf("Default[%dmV]\n",DEFAULT_VREF);

}

#else

if (val_type); // Suppress warning

#endif

Heltec.begin(true /*DisplayEnable Enable*/, false /*LoRa Disable*/, true /*Serial Enable*/);

Heltec.display->flipScreenVertically();

Heltec.display->setFont(ArialMT_Plain_10);

Heltec.display->clear();

#if defined(__DEBUG) && __DEBUG >= 1

Serial.printf("ADC Calibration: ");

if (val_type == ESP_ADC_CAL_VAL_EFUSE_VREF) {

Serial.printf("eFuse Vref\n");

} else if (val_type == ESP_ADC_CAL_VAL_EFUSE_TP) {

Serial.printf("Two Point\n");

} else {

Serial.printf("Default[%dmV]\n",DEFAULT_VREF);

}

#else

if (val_type); // Suppress warning

#endif

// Prime the Sample register

for (uint8_t i = 0;i < VBATT_SMOOTH;i++) {

Sample();

}

pinMode(VBATT_GPIO,OUTPUT);

digitalWrite(VBATT_GPIO, LOW); // ESP32 Lora v2.1 reads on GPIO37 when GPIO21 is low

delay(ADC_READ_STABILIZE); // let GPIO stabilize

}

void loop() {

Heltec.display->clear();

uint16_t voltage = Sample();

drawBattery(voltage, voltage < LIGHT_SLEEP_VOLTAGE);

Heltec.display->display();

if (voltage < MINBATT) { // Low Voltage cut off shut down to protect battery as long as possible

Heltec.display->setColor(WHITE);

Heltec.display->setFont(ArialMT_Plain_10);

Heltec.display->setTextAlignment(TEXT_ALIGN_CENTER);

Heltec.display->drawString(64,24,"Shutdown!!");

Heltec.display->display();

delay(2000);

#if defined(__DEBUG) && __DEBUG > 0

Serial.printf(" !! Shutting down...low battery volotage: %dmV.\n",voltage);

delay(10);

#endif

esp_sleep_enable_timer_wakeup(LO_BATT_SLEEP_TIME);

esp_deep_sleep_start();

} else if (voltage < LIGHT_SLEEP_VOLTAGE) { // Use light sleep once on battery

uint64_t s = VBATT_SAMPLE;

#if defined(__DEBUG) && __DEBUG > 0

Serial.printf(" - Light Sleep (%dms)...battery volotage: %dmV.\n",(int)s,voltage);

delay(20);

#endif

esp_sleep_enable_timer_wakeup(s*1000); // Light Sleep does not flush buffer

esp_light_sleep_start();

}

delay(ADC_READ_STABILIZE);

}

// Poll the proper ADC for VBatt on Heltec Lora 32 with GPIO21 toggled

uint16_t ReadVBatt() {

uint16_t reading = 666;

digitalWrite(VBATT_GPIO, LOW); // ESP32 Lora v2.1 reads on GPIO37 when GPIO21 is low

delay(ADC_READ_STABILIZE); // let GPIO stabilize

#if (defined(HELTEC_V2_1))

pinMode(ADC1_CHANNEL_1, OPEN_DRAIN); // ADC GPIO37

reading = adc1_get_raw(ADC1_CHANNEL_1);

pinMode(ADC1_CHANNEL_1, INPUT); // Disconnect ADC before GPIO goes back high so we protect ADC from direct connect to VBATT (i.e. no divider)

#else

pinMode(ADC2_CHANNEL_4, OPEN_DRAIN); // ADC GPIO13

adc2_get_raw(ADC2_CHANNEL_4,ADC_WIDTH_BIT_12,&reading);

pinMode(ADC2_CHANNEL_4, INPUT); // Disconnect ADC before GPIO goes back high so we protect ADC from direct connect to VBATT (i.e. no divider

#endif

uint16_t voltage = esp_adc_cal_raw_to_voltage(reading, adc_chars);

voltage*=VOLTAGE_DIVIDER;

return voltage;

}

// Use a buffer to average/sample ADC

uint16_t Sample() {

static uint8_t i = 0;

static uint16_t samp[VBATT_SMOOTH];

static int32_t t = 0;

static bool f = true;

if(f){ for(uint8_t c=0;c<VBATT_SMOOTH;c++){ samp[c]=0; } f=false; } // Initialize the sample array first time

t -= samp[i]; // doing a rolling recording, so remove the old rolled around value out of total and get ready to put new one in.

if (t<0) {t = 0;}

// ADC read

uint16_t voltage = ReadVBatt();

samp[i]=voltage;

#if defined(__DEBUG) && __DEBUG > 0

Serial.printf("ADC Raw Reading[%d]: %d", i, voltage);

#endif

t += samp[i];

if(++i >= VBATT_SMOOTH) {i=0;}

uint16_t s = round(((float)t / (float)VBATT_SMOOTH));

#if defined(__DEBUG) && __DEBUG > 0

Serial.printf(" Smoothed of %d/%d = %d\n",t,VBATT_SMOOTH,s);

#endif

return s;

}

void drawBattery(uint16_t voltage, bool sleep) {

Heltec.display->setColor(BLACK);

Heltec.display->fillRect(99,0,29,24);

Heltec.display->setColor(WHITE);

Heltec.display->drawRect(104,0,12,6);

Heltec.display->fillRect(116,2,1,2);

uint16_t v = voltage;

if (v < MINBATT) {v = MINBATT;}

if (v > MAXBATT) {v = MAXBATT;}

double pct = map(v,MINBATT,MAXBATT,0,100);

uint8_t bars = round(pct / 10.0);

Heltec.display->fillRect(105,1,bars,4);

Heltec.display->setFont(ArialMT_Plain_10);

Heltec.display->setTextAlignment(TEXT_ALIGN_RIGHT);

// Draw small "z" when using sleep

if (sleep > 0) {

Heltec.display->drawHorizontalLine(121,0,4);

Heltec.display->drawHorizontalLine(121,5,4);

Heltec.display->setPixel(124,1);

Heltec.display->setPixel(123,2);

Heltec.display->setPixel(122,3);

Heltec.display->setPixel(121,4);

}

Heltec.display->drawString(127,5,String((int)round(pct))+"%");

Heltec.display->drawString(127,14,String(round(voltage/10.0)/100.0)+"V");

#if defined(__DEBUG) && __DEBUG > 0

static uint8_t c = 0;

if ((c++ % 10) == 0) {

c = 1;

Serial.printf("VBAT: %dmV [%4.1f%%] %d bars\n", voltage, pct, bars);

}

#endif

}