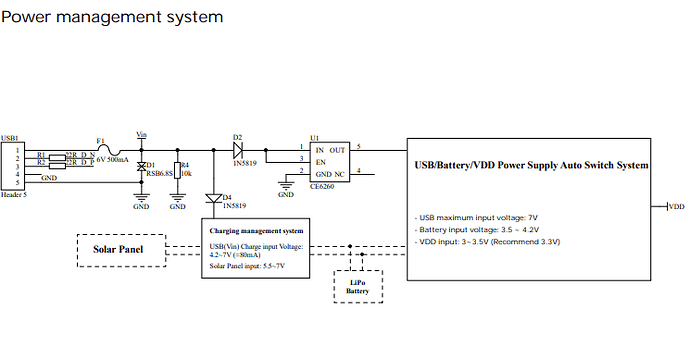

Due to how the charging/power management/power switching is implemented on the CubeCell boards, I am unable to determine the following:

-When is it on external power (USB)

-When is it charging. I need this to compensate for self-heating during charging.

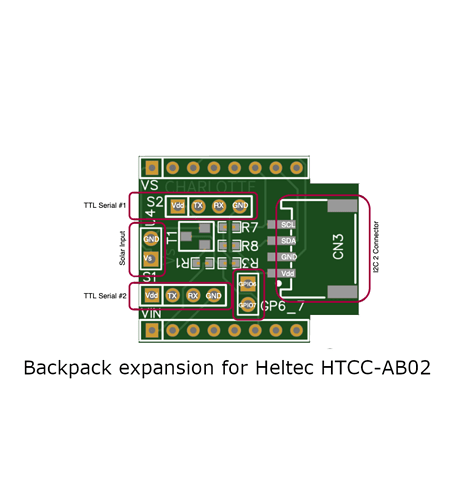

Can we get the option on the next version of boards to have a set of bridge pads to tie these to a GPIO?

My reason for this is to alter the behaviour and transmit interval based on the state of the power system.

While I am asking, a current sensor for the battery such as the INA219 would be a nice addition to the boards.

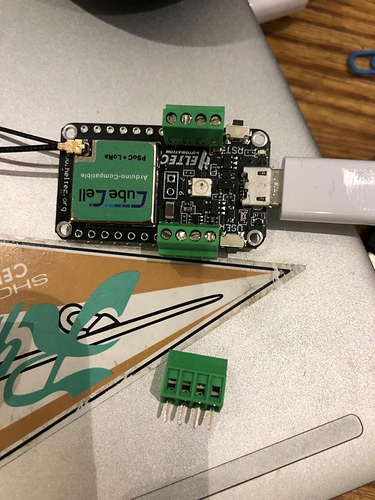

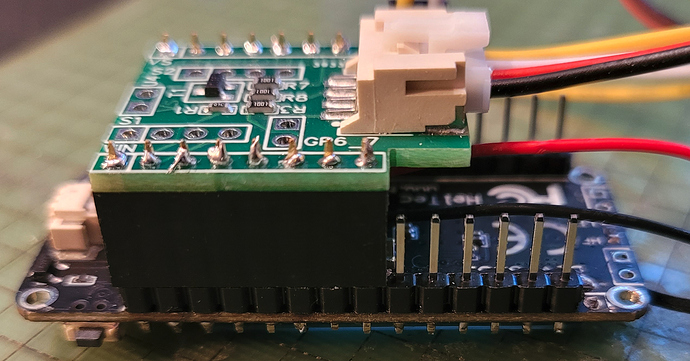

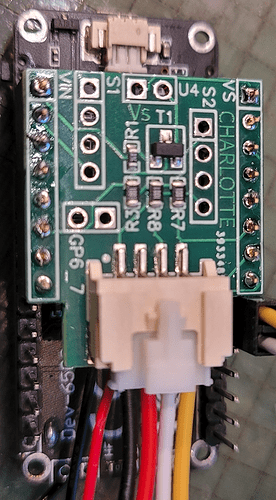

If anyone knows of a way to achieve these requests with the current boards it would be appreciated (I am using the Cubecell board and Dev-plus boards).

thanks,

-michael

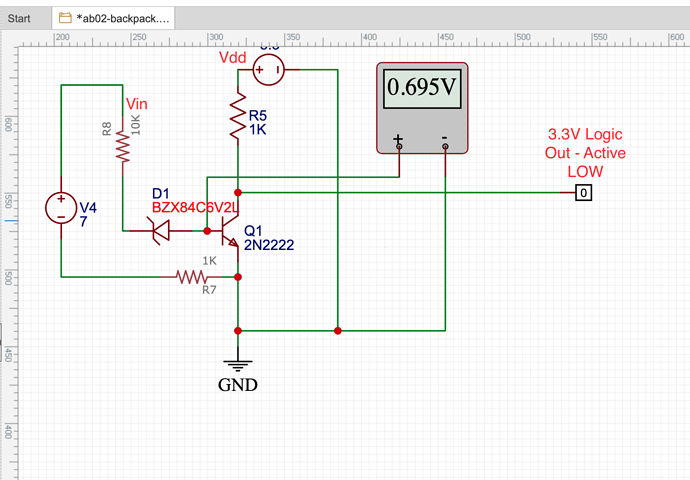

. It is low when the chip is actually charging the battery. but you must be careful - there seem to be different types of that chip on different production charges - some of these deliver 3.3V as high, some 5V. In the 5V case you need the voltage divider / MOSFET circuit before you connect the signal to a GPIO.

. It is low when the chip is actually charging the battery. but you must be careful - there seem to be different types of that chip on different production charges - some of these deliver 3.3V as high, some 5V. In the 5V case you need the voltage divider / MOSFET circuit before you connect the signal to a GPIO.