CubeCell Capsule Waterproofing

The CubeCell Capsule comes in both “non porous” and” porous” transparent shell version dependant on the sensor ordered or what is purchased. The basic capsule would meet for the porous version IP32/IP42 based on the size of the vent hole. For the non-porous version, it should meet IP63 in the supplied state.

For some application having it water proofed is a requirement and while in the supplied form it is best “splash proof” it can be made to meet IP67 with the addition of 2 “O” rings.

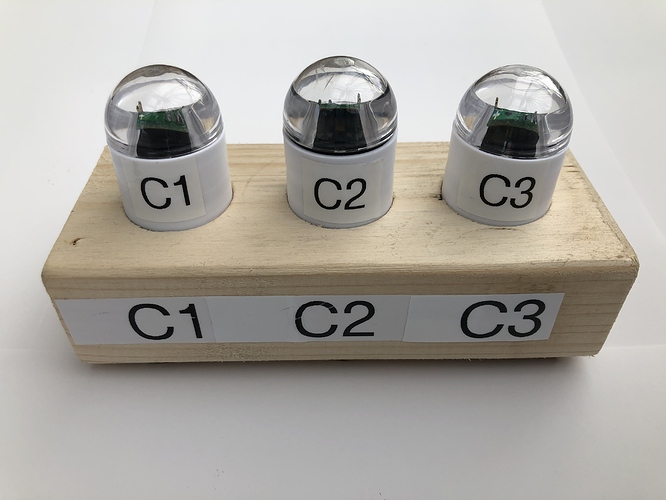

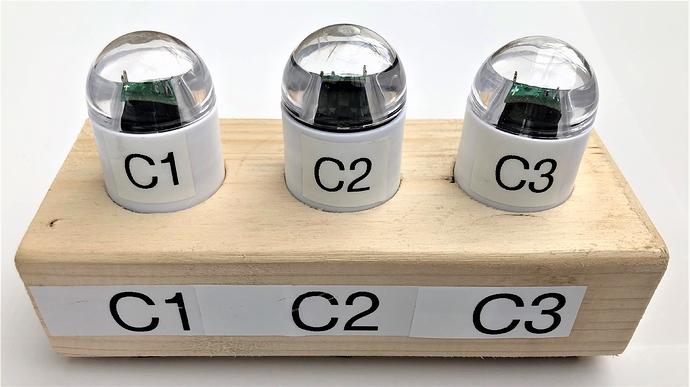

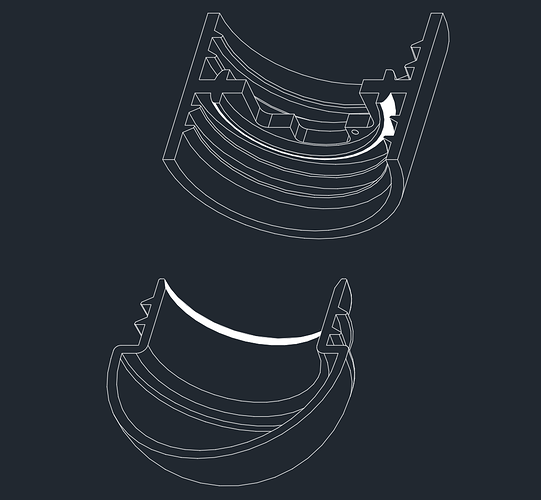

The pictures below shows the “O” ring on one end fitted and not fitted on the other of the non-porous Capsule. The “O” ring size used was 24mm x 1.8mm placed over the capsule end seated against the ridge, this hold well and under tension. Theses “O” rings should be lightly covered in silicone grease to enable easier application and better long-term seal.

I have tested the capsule for the 30 minutes at 1M depth of water required and fully meet the spec.

Note. The Capsules can only be water-proofed if they have a sensor installed that does not require free air movement e.g. MPU9250, BH1750.

Simon

just the way I laid it up I will update.

just the way I laid it up I will update.